We value your privacy

We use cookies to enhance your browsing experience, serve personalized ads or content, and analyze our traffic. By clicking "Accept All", you consent to our use of cookies.

We use cookies to help you navigate efficiently and perform certain functions. You will find detailed information about all cookies under each consent category below.

The cookies that are categorized as "Necessary" are stored on your browser as they are essential for enabling the basic functionalities of the site. ...

Necessary cookies are required to enable the basic features of this site, such as providing secure log-in or adjusting your consent preferences. These cookies do not store any personally identifiable data.

Functional cookies help perform certain functionalities like sharing the content of the website on social media platforms, collecting feedback, and other third-party features.

No cookies to display.

Analytical cookies are used to understand how visitors interact with the website. These cookies help provide information on metrics such as the number of visitors, bounce rate, traffic source, etc.

Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors.

Advertisement cookies are used to provide visitors with customized advertisements based on the pages you visited previously and to analyze the effectiveness of the ad campaigns.

Hicof is dedicated to providing comprehensive packaging solutions that meet the demanding requirements of the food industry. Our end-packaging systems enhance production efficiency while ensuring each packaged product meets stringent hygiene and safety standards. With a focus on compact design, robust construction, and user-friendly operation, our casepackers set the standard for food end-packaging.

Two flagship solutions in our portfolio are the AMAPACKER‑150 and the AMAPACKER‑A300. Both machines are designed with a complete integration of aggregation software out of the box, providing a seamless solution that covers everything from case packing to advanced product aggregation.

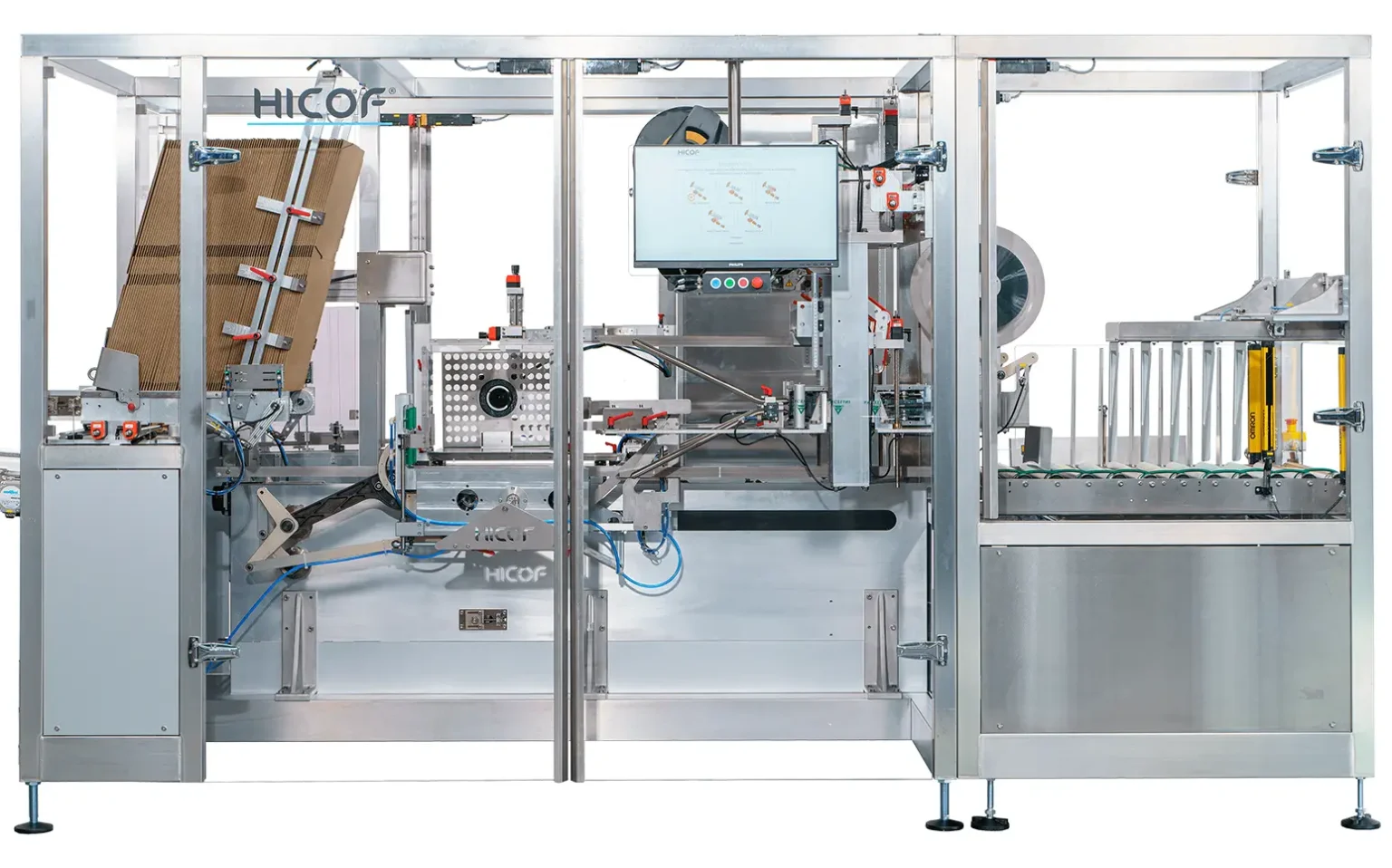

For high‑volume operations requiring maximum throughput and complete automation, the AMAPACKER‑A300 is the premier choice. This fully‑automatic casepacker is designed to deliver unmatched performance and operational reliability, with a suite of features that ensure a streamlined, efficient packaging process.

The fully‑automatic AMAPACKER‑A300 is tailored for operations that require maximum speed and full automation. It is ideally suited for:

One of the key advantages of Hicof’s Food Packaging solutions is the seamless integration of aggregation software with both the AMAPACKER‑150 and the AMAPACKER‑A300. This built‑in software ensures that data from each packaging operation is aggregated in real‑time, providing comprehensive traceability and control across your entire production process.

By offering both the semi‑automatic and fully‑automatic casepackers with integrated aggregation software, Hicof provides a comprehensive, plug‑and‑play solution that streamlines your Food Packaging operations.

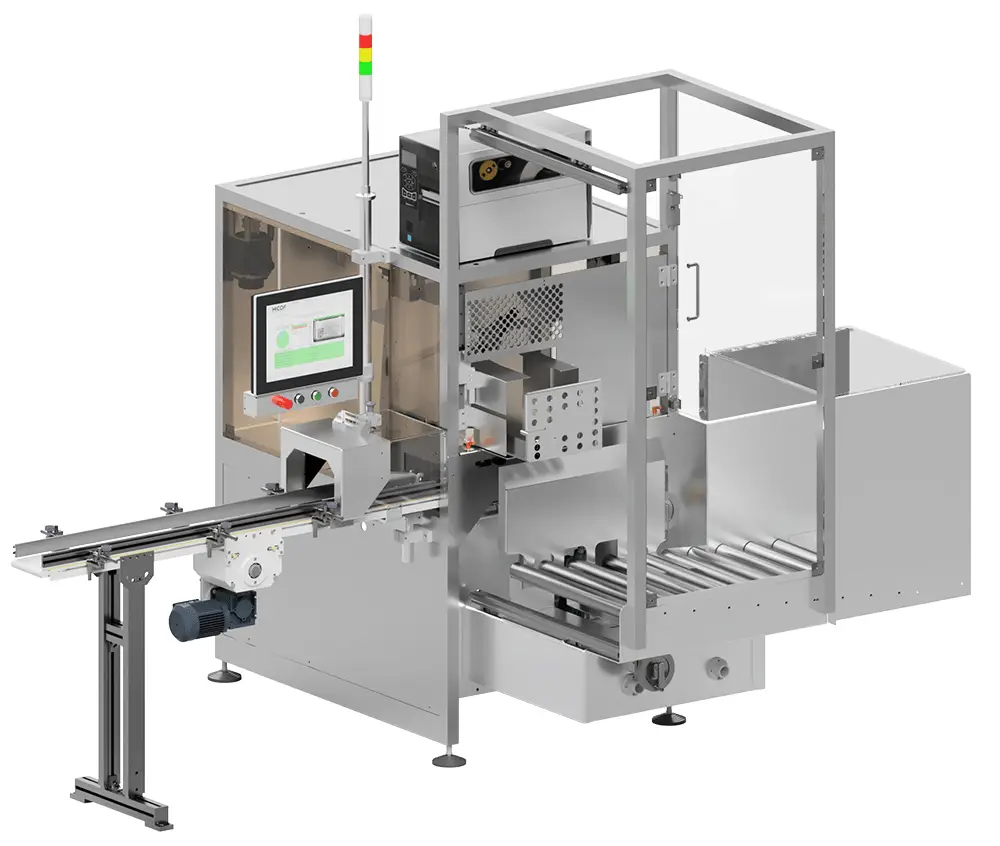

The AMAPACKER‑150 is a semi‑automatic casepacker engineered for high performance in environments where space is limited, yet efficiency cannot be compromised. This machine is the ideal choice for operations that require a flexible, compact solution without sacrificing throughput or quality.

The AMAPACKER‑150 is ideally suited for medium‑scale operations where flexibility and space efficiency are required. It is perfect for:

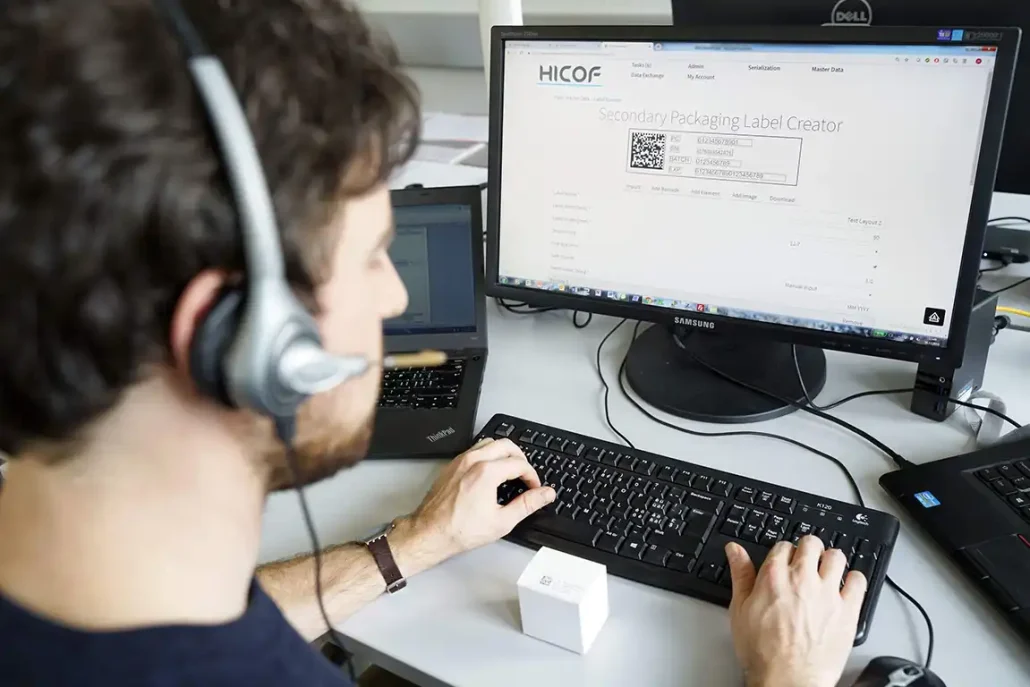

Hicof AMACENA features a build-in web based label creator to create and adjust all print layouts for AMACODERS, and all connected tertiary label printers. The label creator allows GMP compliant change control of all label parameters across the enterprise.

Hicof’s commitment to excellence in food end-packaging is reflected in our innovative machine designs, robust construction, and integrated software solutions. Here’s why industry leaders choose Hicof:

Hicof’s approach to Food Packaging goes beyond providing high‑performance machines and integrated software; it’s about ensuring that your facility achieves a smooth and successful transition to advanced, automated packaging solutions.

In the competitive world of food production, an effective end-packaging solution is crucial for ensuring product integrity, hygiene compliance, and operational efficiency. Hicof’s advanced casepackers—the semi-automatic AMAPACKER-150 and the fully-automatic AMAPACKER-A300—are designed to meet the highest standards of performance, safety, and efficiency.

Featuring:

Hicof provides the ultimate solution for food packaging. Our systems ensure that your packaging operations are not only compliant with stringent regulatory requirements but also optimized for maximum efficiency and safety.

By choosing Hicof, you invest in a future‑proof solution that delivers:

Contact us today to discover how Hicof’s Food Packaging solutions can transform your packaging line, improve operational efficiency, and secure your supply chain in the competitive foodindustry landscape. Embrace the power of innovation, quality, and integrated design with Hicof—your trusted partner in advanced Food Packaging technology.